CMMS/TPM Maintenance Software

The Eight Pillars of Total Productive Maintenance include:

- Autonomous Maintenance.

- Planned Maintenance.

- Quality Maintenance.

- Focused Improvement.

- Early Equipment Management.

- Training and Education.

- Safety, Health, Environment.

- TPM in Administration.

The Connections Of CMMS/TPM Maintenance

Total Lean Management (TLM) Software can be used for multiple aspects of what should be happening in an integrated digital landscape of interconnected processes.

Whether you are trying to meet objectives within quality management system software, risk management software, CMMS Maintenance Software, or Material Management software, having a foundation of integrated tpm maintenance software modules to build your solution on enables the most options to ultimately meet the needs of the employees tasked with implementing, managing, and continuously improving these systems.

Implement your

Perfect Solution

with the following modulesAutonomous Maintenance

This principle puts the responsibility of routine maintenance in the hands of the equipment operators. It provides...

Planned Maintenance

TLM Document Control software leverages the effort spent on your company’s documentation and...

Quality Maintenance

This pillar of TPM involves designing error detection and prevention into the production process. It also...

Focused Improvement

Use small cross functional teams to collaborate on developing incremental improvements in...

Early Equipment Management

When a company can have an impact on equipment design, this category aims at taking knowledge gained in...

Training And Education

Knowledge gained from TPM activities as well as knowledge from company procedures, equipment manufacturers...

Safety, Health, Environment

Eliminating potential health and safety risks to create an accident-free workplace needs to be captured in company...

TPM In Administration

quipment availability can also be impacted by administrative issues. To avoid these issues, a company needs solid...

FAQs

WHAT Is TPM?

Total Productive Maintenance is a principle based methodology, and holistic approach to equipment maintenance aimed at maximizing production with tpm maintenance software by eliminating all the causes of equipment downtime, such as:

- Breakdowns.

- Delays.

- Defects.

- Accidents.

One of the key aspects of the TPM program is that it emphasizes the necessity for everyone who is involved with equipment in any way to be responsible and proactive about maintenance. This includes:

- Operators.

- Maintenance personnel.

- Management.

What is CMMS?

What does CMMS software do?

Can I have a free trial of the solution?

Why do we need CMMS?

Your testing and production equipment can have a significant impact on the quality of your products when any kind of equipment is being used for their manufacture or testing. CMMS software helps you keep track of maintenance and calibration requirements and make sure those are assigned and performed on-time and on-schedule.

But that is just the beginning. What you also need could involve relationships to other parts of the QMS. For example, can you link your equipment to non-conformance reporting and generate reports on the trends of which equipment has been involved in the most issues?

The Fusion Technology in Total Lean Management (TLM) QMS Software is a result of inter-module linking so that equipment can be linked to any other relevant area of the QMS. This might include:

- Training

- Procedures

- Parts

- Non-Conformances

- Deviations

- Corrective Actions

- Inspections

- Work orders (Production and Maintenance)

- Vendors / Equipment Suppliers

So while you could pay for and accumulate separate software for all these categories, you are going to have much better information that costs less if you find a QMS Software system that has everything integrated, like TLM.

What is total productive maintenance?

Total Productive Maintenance, or TPM, is an 8 pillar philosophy of engaging the entire organization in maintenance on the foundation of 5S (Sort, Straighten, Shine, Standardize, and Sustain) with the goal of getting as close to 100% equipment availability as possible.

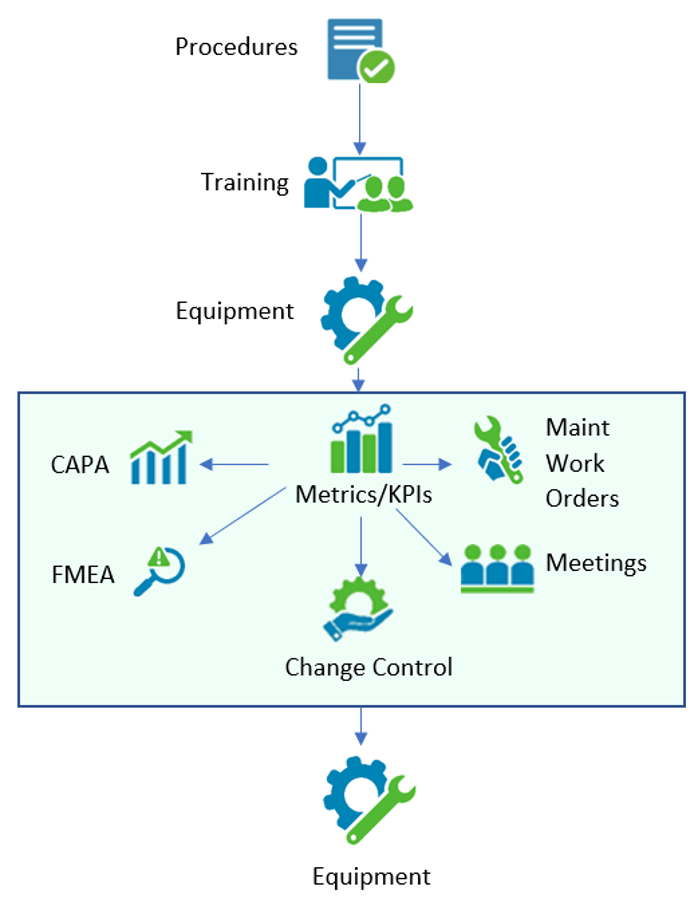

As a result, software to support a solid TPM program would need to address many aspects of an organization beyond what CMMS software usually does, to include procedures, policies, training, management reviews, metrics, equipment maintenance, risk analysis (links to DFMEA, PFMEA and Control Plans) project management, purchase orders, work orders, inventory, vendor management, tools to support Kaizen Initiatives like value stream mapping with both time and cost projections, and perhaps audits, with solid KPI reporting.

Basically, you would need Total Lean Management software to fully wrap software around all the activities involved in building a comprehensive TPM program. Want to see how that can be accomplished? Schedule a demo with us and we’ll show you how TPM can be accomplished with TLM.

What are the objectives of TPM?

There is Only One Type of Quality Management System

Yours!

Over the last 20 years TLM has discovered a very basic truth when it comes to information management systems such as your eQMS, no two companies have the exact same needs.

In fact, the two biggest risks in the software selection process is either selecting software that is not flexible enough to manage information that is unique, and important to your workflow, thus forcing work arounds, or other concessions that effectively add waste to your business.

The other mistake is getting stuck with comprehensive, but inflexible quality management solutions due to their web based cloud hosting design, which forces a one size fits all approach to meeting customer needs.

And while one size might fit some, it might not fit all your needs when in the long run your understanding of those needs evolves and improves.

Total Lean Management Software, by definition, recognizes this fact, and addresses quality management solutions through a dual technology, upstream / downstream user landscape approach to meeting the needs of both your upstream and downstream user types. This is combined with our tiered approach to addressing newly discovered customer needs, making sure the software works in alignment with your business systems the day after your purchase, and for all the years ahead.

TLM Workflow Support:

Custom fields

Allows you to adapt the software to your company’s terminology.

System Settings

Allows you to choose which features are applied to your process.

Rapid update cycles

Incorporating employee feedback into the continuous improvement cycle creates a synergistic effect on moral, engagement, and productivity.

Development Projects

This capability provides insurance that your system will never leave you stuck after discovering unknown needs after implementation.

High levels of interlinking

By implementing and combining modules in way that might be unique to your business or work flows.

World class customer support

Evolution is a team effort, and the whole team behind TLM enjoys helping companies comply with regulations, manage risk, continuously improve, and maintain a steady growth rate.

Help Files can be Linked to your Controlled Work Instructions

This unique TLM feature allows you to link individual screens in TLM to your own controlled procedures or work instructions for that area of the software (if needed)..

Why TLM is your Best QMS Software Choice

TLM Delivers Your Solution

Out of the box, or with a few customizations, our QMS Software is backed by a 100% success rate for over 2 decades getting companies ISO certified on the first try!

If you have any questions or want more detailed information, do not hesitate to call us (866) 209-6896.

“TLM Customers are always our top priority” -David Smithstein, CEO

“In the 10 years that we have relied on TLM to manage our quality documents, it has grown to become the core of our QMS. Our QMS has been audited by BSI, TUV, SAI, FDA, Canada Health and CDPH . We survived all of those audits and emerged a better company. Thanks, David!”

Jim Klett

“EXCELLENT customer service! Without fail, David has responded to every question, email and phone call within a few hours. He is great to work with and always willing to help… TLM is a one-stop shop for all of our QMS needs … The training videos on the website are helpful- keep them coming!”

Allison Getz

“Very helpful in fine-tuning the software/reports to meet our specific needs for audits, even ones requested the day before the audit. The software is straight forward for use, we have 8 personnel in two different locations using it seamlessly … The best customer support I have ever used.”

Stewart Denham

Quality Integrated with Efficiency

Demos

Demos